Injection Molds

As part of our integrated manufacturing services, Cir-Q-Tek offers plastics injection molding solutions. Our injection molding services are competitively priced to help companies remain profitable in competitive markets. No matter how unique the request, we can provide a quick turnaround.

Our end-to-end injection molding services cover everything from design assistance, mold creation, and tooling to prototyping, production, and quality inspection. We work with an extensive range of thermoplastics and meet the most challenging aesthetic, mechanical, thermal, and optical properties. Some examples of materials we commonly mold include ABS, high-strength PEI, general-purpose PBT, high-performance polyesters, glass-filled resins, and dimensionally stable, high-heat PPS grades.

We have capabilities for two-shot molding using two different polymers and in-mold assembly to embed a metal insert into a plastic part for increased strength. Depending on the material and the specifications, we can achieve injection molding tolerances as close as ±0.003”.

Our injection molding processes are highly automated and computer monitored to promote process stability. They also include in-process quality controls to ensure part accuracy and repeatability. We operate a structured, lean manufacturing environment, and our quality program is certified to ISO 9001, ISO 13485, and IATF 16949 standards. For more information about our versatile injection molding capabilities, request a quote, or contact us directly.

Precision Machining Services

Cir-Q-Tek offers precision class CNC machining services with tight tolerance machining to produce parts in any size, shape, or quantity. We provide engineering services to assist with part design and create innovative solutions to machining and manufacturing challenges. Our precision CNC machining services include high-performance milling and turning equipment, including multi-axis, multi-tasking machinery capable of producing finished parts from a single setup. Features like live tooling and multiple spindles allow us to create components with complex geometries and intricate features while upholding tolerances as close as ±0.0005”. Our machining services are backed up by unparalleled CAD design and CAM programming expertise, which facilitates the machining process and ensures the highest level of accuracy and repeatability. We supply precision machined parts made from almost any material. Along with standard grade and high-strength, high-temperature metals and alloys, we work with engineered plastics and other non-metals, like ceramic, composites, etc. We also have unique expertise for finish machining aluminum, zinc, magnesium, iron, and stainless steel castings. All machining takes place in ISO 9001, ISO 13485, and IATF 16949 certified facilities. Parts are inspected using high-end metrology equipment and under strict supervision. We can also stock parts and ship them for just-in-time delivery. We work within customer schedules and have an outstanding track record for meeting our delivery commitments. To learn more about our precision CNC machining capabilities, request a quote, or contact us directly.

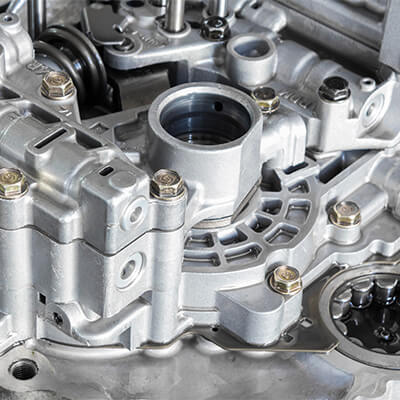

High Quality Die Casting Services

Cir-Q-Tek provides all-in-one solutions for precision die-cast products with a range of specifications. Our services utilize state-of-the-art, automation-driven die casting technologies and combine them with precision CNC machining, surface finishing, and ISO-certified quality inspection. With die casting machines ranging from 125 tons to 1,650 tons, we provide die casting services for miniature components up to large and heavy workpieces. We use technically advanced die casting software to design molds and perform extensive flow and thermal performance analytics. We work with dry sand, oil sand and investment casting molds. We also can use wax molds based on application variables. We are proficient at aluminum, zinc, and magnesium die casting and offer custom alloying to obtain a specific set of performance characteristics. Our capabilities also include die casting non-metals such as acrylic, graphite, polyurethane, and other resins. When necessary, we can finish machine die-cast parts to precise tolerances. We have extensive capabilities in CNC machining and can obtain tolerances as close as ±0.0005” on critical components. We also have facilities for heat treating, plating, powder coating, etc. Quality assurance involves CMM inspection, salt-spray testing, spectrometry, and other test and inspection processes per customer specifications. We operate with lean efficiency, and our die casting services are certified to ISO 9001, ISO 13485, and IATF 16949 standards. We deliver finished goods, on time, that exhibit the highest caliber of quality. To learn more about our versatile die casting operations, request a quote, or contact us directly.

Wire Harness

Cir-Q-Tek provides high-quality solutions for custom wire harnesses. We have an extensive history in wire harness manufacturing and offer best-in-class services at competitive pricing. Our wire harness services are certified to ISO 9001, ISO 13485, and IATF 16949. We supply wire harnesses to customers in diverse industries, including industrial process control, telecom, gaming, product dispensing, audio and video, computer, medical, health-care, and automotive. With our turnkey capabilities, we provide a full suite of services, from interconnect design to production and packaging. Our facilities house the newest technology equipment for wire stripping, cutting, preparation, and assembly. All technicians are qualified to IPC standards for wire harness assembly and are accustomed to preparing wiring and cable harnesses for complex electronics and instrumentation. We offer a multitude of options for connectors, wire sizes, wraps, insulation, labeling, etc., and can produce wire harness assemblies to survive in any type of environment. For high-volume projects, we stock and distribute wire harnesses for just-in-time delivery. Customers can also combine wire harness manufacturing with our other services, such as PCB assembly or plastic injection molding. We handle small orders as well as those that involve millions of units. To learn more about our wire harness manufacturing capabilities, request a quote, or contact us directly.

Rigid and Flexible Printed Circuit Boards

Cir-Q-Tek has established a name for itself in the printed circuit board industry by specializing in both quick turn prototypes and production manufacturing. And when we say “quick-turn,” we mean it. For pre-production and prototype samples, it generally takes three days to build and two days to ship to your dock. For production and manufacturing, your product will be ready to ship in ten days to four weeks.

With our Asian facilities, we make it possible for your company to reap the benefits of offshore pricing. Count on us to provide high-quality, low-cost printed circuit boards with a timely delivery to our domestic customers.

We can meet your requirements for all types of PCBs: single-sided, double-sided and multi-layer. Our approach is to identify and utilize the most cost-efficient circuit board manufacturing practices available for your specific project. From design to fabrication—we take care of it all.

PRECISE INSPECTION

Our quality control process ensures your full satisfaction. All materials and components are inspected at each stage of production and every finished product is scrutinized before delivery—to ensure that they conform with IPC specifications and standards, while meeting your requirements. This guarantees that the end product will be the right solution for your needs.

IN-STEP WITH TECHNOLOGICAL ADVANCES

Cir-Q-Tek stays at the forefront of the industry to meet the demands and ever-changing requirements of our customers. Our specialized team of experts is always incorporating new ways to utilize the latest advances in technology.

We offer single sided, up to and including 40 layer multilayers. Also, blind and buried via, impedence control, and laser drilled holes down to .0039” mils. In addition, our sources are using a wide range of esoteric substrates which include mixed technology lamination. We are producing products with lines and spacing down to .0025”/.0025” mils. All of our PCB products can be made to RoHS (Restriction of Hazardous Substances) specifications, and all of our sources offer the latest millennium metallic finishes. These finishes include: HASL (Hot Air Solder Leveling), HAL (Hot Air Lead-Free Leveling), ENIG (Immersion Nickel/Gold), Immersion Silver, Immersion Tin, and ENTEK 106 A-HT which is an OSP (Organic Solderability Preservative)…just to name a few.

In addition, Cir-Q-Tek utilizes the process of laser direct imaging that gives you a substantial advantage over traditional methods by eliminating the possibility of distortion, shrinkage, or positional errors.

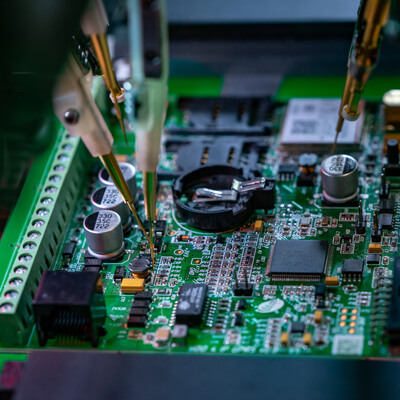

Printed Circuit Board Assembly

Cir-Q-Tek provides high-quality circuit board assemblies with no compromise. Best Quality / Best Pricing / and On Time delivery. We have an extensive history in circuit board assemblies, and offer best-in-class services with highly competitive pricing. Our assembly services are certified to ISO 9001 and ISO 13485 and IATF 16949 for medical and automotive devices. We supply assemblies to customers in diverse industries including industrial process control, telecom, gaming, product dispensing, audio and video, computer, medical, health-care, and automotive. With our turnkey capabilities, we provide a full suite of services which includes complete box builds and packaging.

Our facilities house the newest technology equipment for one-stop comprehensive assembly service integrating PCB manufacturing, electronic component purchasing, SMT chip processing, through-hole assembly, testing and complete box build assembly. Each of our SMT lines contains AOI and Xray equipment for inline automated inspection. Our facility equipment is tailor-made for sample and small batch production, staying ahead of industry technology, and can paste 01005, BGA spacing of 0.2mm, QFN, CSP, and other components. We are a one-stop integrated manufacturing service provider.

We handle small prototype orders as well as production quantities. To learn more about our circuit board assembly capabilities, request a quote, or contact us directly.